Pipe corrosion is a natural process that occurs over time, causing damage to pipes and infrastructure. Understanding how pipe corrosion works is essential for maintaining the integrity of plumbing systems, industrial pipelines, and other critical infrastructure. In this blog post, we’ll explore the mechanisms behind pipe corrosion, its causes, and ways to prevent it.

The Basics of Pipe Corrosion

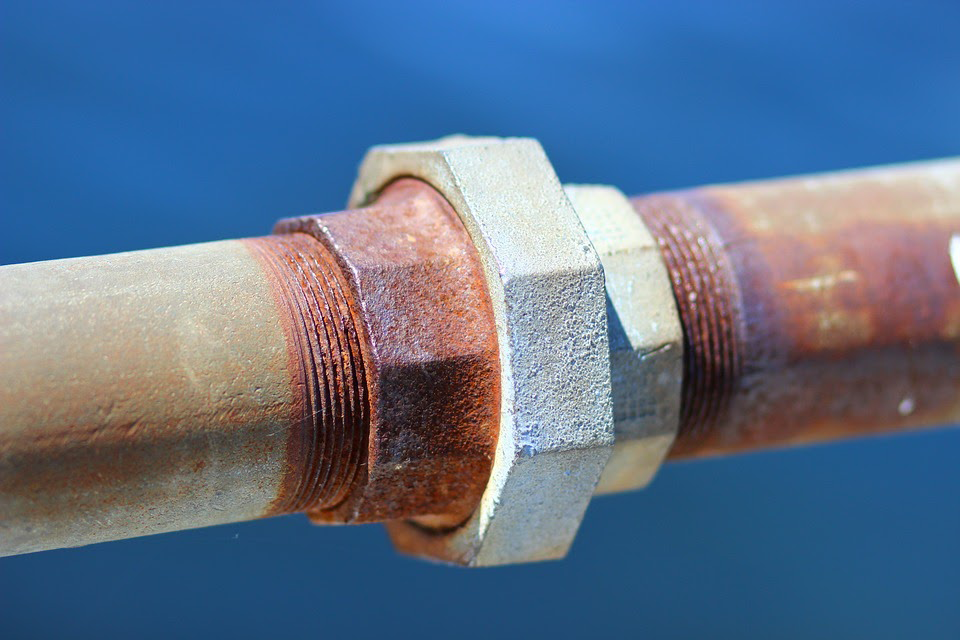

Corrosion is a chemical process in which metal materials react with their environment, leading to the deterioration of the metal. In the context of pipes, this can result in reduced functionality, leaks, and even structural damage. Pipe corrosion occurs primarily due to electrochemical reactions, and several key factors contribute to this process.

- Electrochemical Reactions: Corrosion involves the flow of electrons between two different metals or materials within the pipe system. This flow of electrons leads to the formation of compounds that weaken the metal’s structure. The primary electrochemical reactions responsible for pipe corrosion include oxidation and reduction processes.

- Oxidation and Reduction: Oxidation involves the loss of electrons from a metal, resulting in the formation of metal ions. This process often occurs at the anode, which is the part of the metal where corrosion initiates. Reduction, on the other hand, is the gain of electrons, typically occurring at the cathode. This process completes the electrochemical circuit and facilitates the corrosion process.

- Electrolytes: For corrosion to occur, there must be a conductive medium to facilitate the flow of electrons. In most cases, water serves as the electrolyte, allowing ions to move between the anode and cathode. The presence of dissolved salts and impurities in the water can accelerate the corrosion process.

Causes of Pipe Corrosion

Pipe corrosion can be attributed to several factors, both internal and external. Understanding these causes is crucial for effective corrosion prevention. Some common causes of pipe corrosion include:

- Chemical Reactions: The presence of aggressive chemicals in the fluid flowing through pipes can accelerate corrosion. Acids, alkalis, and corrosive gases can all contribute to the breakdown of metal materials.

- Oxygen Exposure: Oxygen is a major contributor to corrosion, especially in the presence of moisture. Oxygen reacts with metals, leading to the formation of oxides that weaken the pipe’s structure.

- Temperature Variations: Rapid temperature fluctuations can cause pipes to expand and contract, leading to stress corrosion cracking. This is especially common in high-temperature industrial environments.

- Microbiologically Induced Corrosion (MIC): Microorganisms such as bacteria can thrive in pipes and produce corrosive byproducts. MIC can lead to localized pitting corrosion, which can be challenging to detect and mitigate.

Preventing Pipe Corrosion

Preventing pipe corrosion is essential to extend the lifespan of pipelines and ensure their safe operation. Here are some strategies to mitigate and prevent corrosion:

- Protective Coatings: Applying protective coatings, such as epoxy, paints, or polymers, can create a barrier between the metal surface and the corrosive environment, reducing the risk of corrosion.

- Cathodic Protection: This technique involves the use of sacrificial anodes or impressed current systems to protect the pipe’s metal from corrosion. Cathodic protection systems supply a flow of electrons to the pipe, preventing oxidation.

- Material Selection: Choosing corrosion-resistant materials for pipe construction, such as stainless steel or plastic, can significantly reduce the susceptibility to corrosion.

- Regular Maintenance: Routine inspections and maintenance can help detect corrosion early and prevent its progression. Cleaning, flushing, and repairing damaged coatings are essential maintenance tasks.

Understanding how pipe corrosion works and its underlying mechanisms is crucial for maintaining the integrity of pipelines and plumbing systems. By identifying the causes and implementing preventive measures, we can ensure that pipes remain durable and safe for extended periods, reducing the risk of costly repairs and environmental hazards associated with pipe corrosion. Regular inspections and maintenance should be a top priority for anyone responsible for managing pipelines and infrastructure.